The Xizi Zero Carbon Smart Energy Center is centered around energy sources such as photovoltaic, molten salt energy storage, electrochemical energy storage, and hydrogen fuel cells. Through the "smart" brain, it organically integrates various new energy and energy storage technologies to provide power, cold, hot, compressed air, and other power, creating a true "zero carbon factory". Photovoltaic power generation: The project adopts rooftop distributed photovoltaic technology and demonstrates the application of battery technologies such as perovskite and heterojunction. The photovoltaic installed capacity is 6MWp, with an annual power generation of 5.3 million kWh. The Xizi Birui factory consumes approximately 5 million kWh of electricity annually, truly achieving a "zero carbon factory".

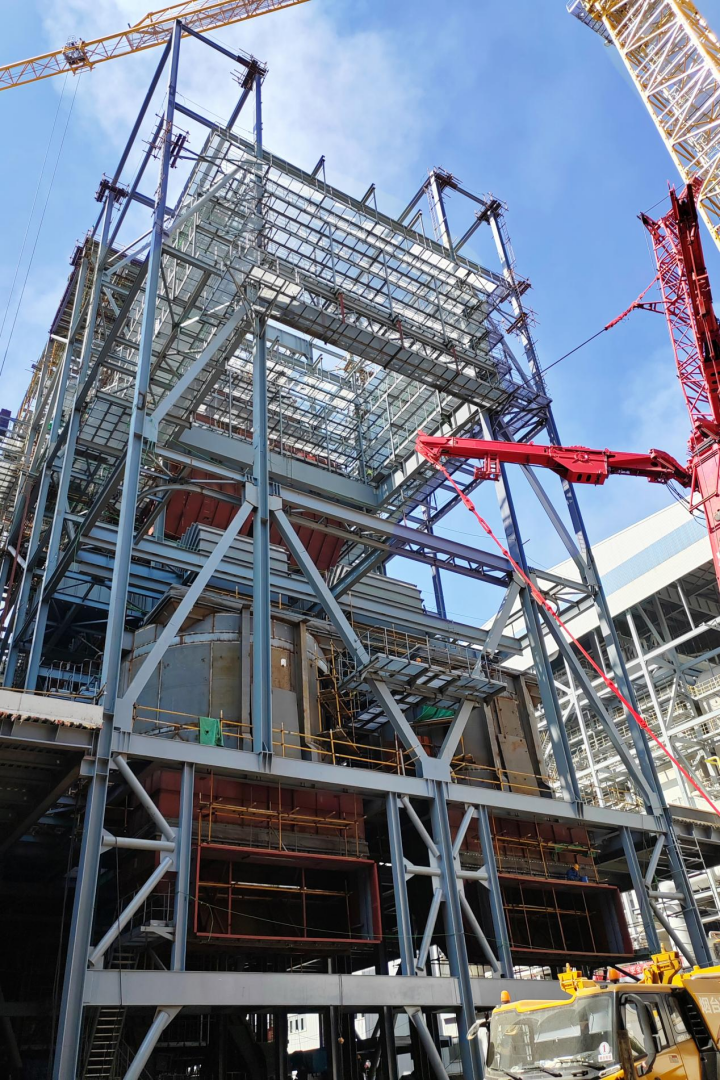

The largest user side molten salt energy storage project in China, undertaken by Xizi Clean Energy, applies the molten salt energy storage technology independently developed by Xizi Clean Energy for many years. It is also the first demonstration project of a chemical fiber green zero carbon industrial park created by the company after Xizi Aviation's zero carbon smart factory, with advantages such as high parameters, high efficiency, long storage time, and low cost. According to calculations, the project can generate 63.7 million kWh of electricity annually, provide 840000 tons of steam annually, save 155000 tons of standard coal annually, and reduce carbon dioxide emissions by approximately 290000 tons.

The project adopts a selective catalytic reduction (SCR) denitration device, with a denitration efficiency higher than 90% for coal fired boilers (with a catalyst arrangement of 3+1) under the conditions of designed and verified coal types, maximum continuous evaporation capacity (BMCR) of boilers, and 100% gas processing.

In order to actively meet national environmental protection requirements, Shanxi Coking Company has invested in the construction of 1 #, 4 #, and 5 # coke oven flue gas desulfurization and denitration devices, which can meet the ultra-low emission requirements of the Linfen region for coke oven pollutants. The coke oven adopts a system configuration of SDS dry desulfurization+bag dust removal+denitration system. Except modification of existing part, a new set of flue gas desulfurization and dust removal system and corresponding supporting facilities was built. The system adopts a technological process of "baking soda dry desulfurization (SDS)+bag dust removal+low-temperature denitration process (SCR)+waste heat recovery+induced draft fan" to ensure that the concentration of particulate matter (standard and dry basis) is ≤ 10mg/Nm3, sulfur dioxide (standard and dry basis) is ≤ 30mg/Nm3, and nitrogen oxides (standard and dry basis) is ≤ 100mg/Nm3.

In order to actively meet national environmental protection requirements, Shanxi Coking Company has invested in the construction of 1 #, 4 #, and 5 # coke oven flue gas desulfurization and denitration devices, which can meet the ultra-low emission requirements of the Linfen region for coke oven pollutants. The coke oven adopts a system configuration of SDS dry desulfurization+bag dust removal+denitration system. Except modification of existing part, a new set of flue gas desulfurization and dust removal system and corresponding supporting facilities was built. The system adopts a technological process of "baking soda dry desulfurization (SDS)+bag dust removal+low-temperature denitration process (SCR)+waste heat recovery+induced draft fan" to ensure that the concentration of particulate matter (standard and dry basis) is ≤ 10mg/Nm3, sulfur dioxide (standard and dry basis) is ≤ 30mg/Nm3, and nitrogen oxides (standard and dry basis) is ≤ 100mg/Nm3.

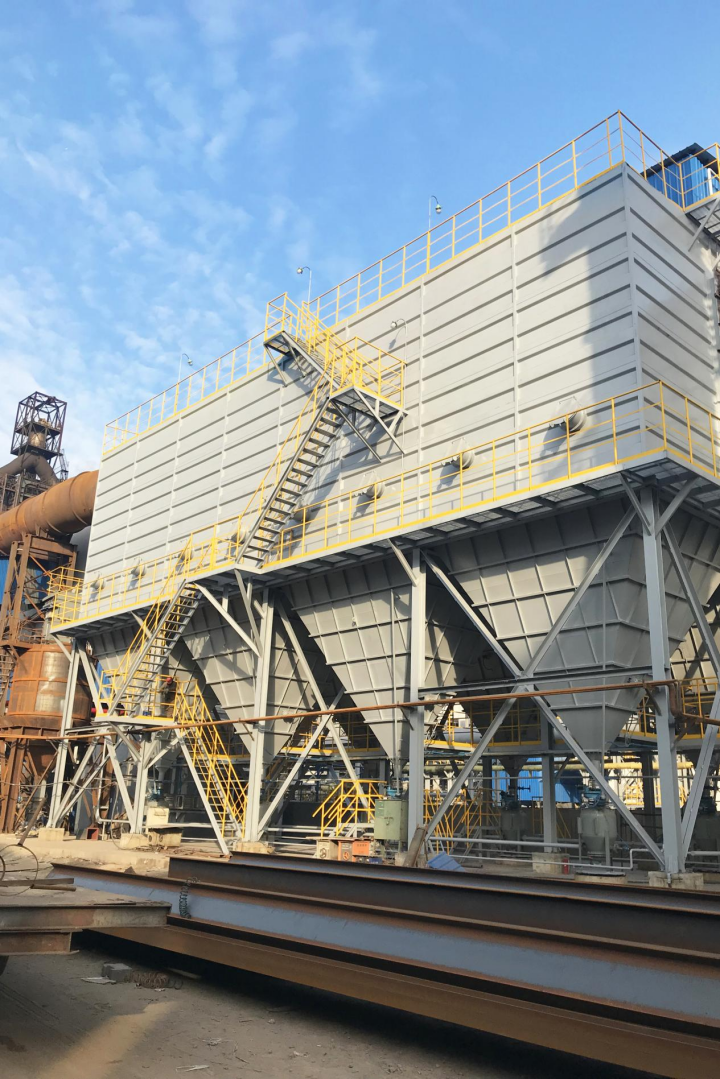

The explosion-proof pulse bag dust collector is used to treat the dust generated during the feeding and transportation process of the blast furnace. After treatment, the emission concentration is ≤ 10mg/m3. The dust is transported pneumatically and the entire process is sealed.

The integrated project of flue gas desulfurization, denitration, dust removal, and purification for the sintering machine of Laiwu Sunshine Metallurgical Co., Ltd. is a supporting environmental protection project for its relocation and construction of a new sintering machine. With the increasingly severe environmental protection situation, the requirements for the emission indicators of various pollutants are becoming increasingly strict. The sintering machine has been treated with flue gas desulfurization, denitration, dust removal, and purification to remove SO2 concentration from 3500mg to below 35 mg/Nm3, NOx ≤ 50mg/Nm3, and dust concentration reduced to below 5mg/Nm3.

This project is aimed at the dust removal system modification of the 75tconsteel continuous feeding electric furnace of Guixin Third Refinery. The electric furnace dust removal system uses flue gas to be led out through a horizontal feeding channel, connected to the settling chamber and quench tower for treatment, and then fed into the dust collector, meeting the environmental protection needs after improving the working conditions.