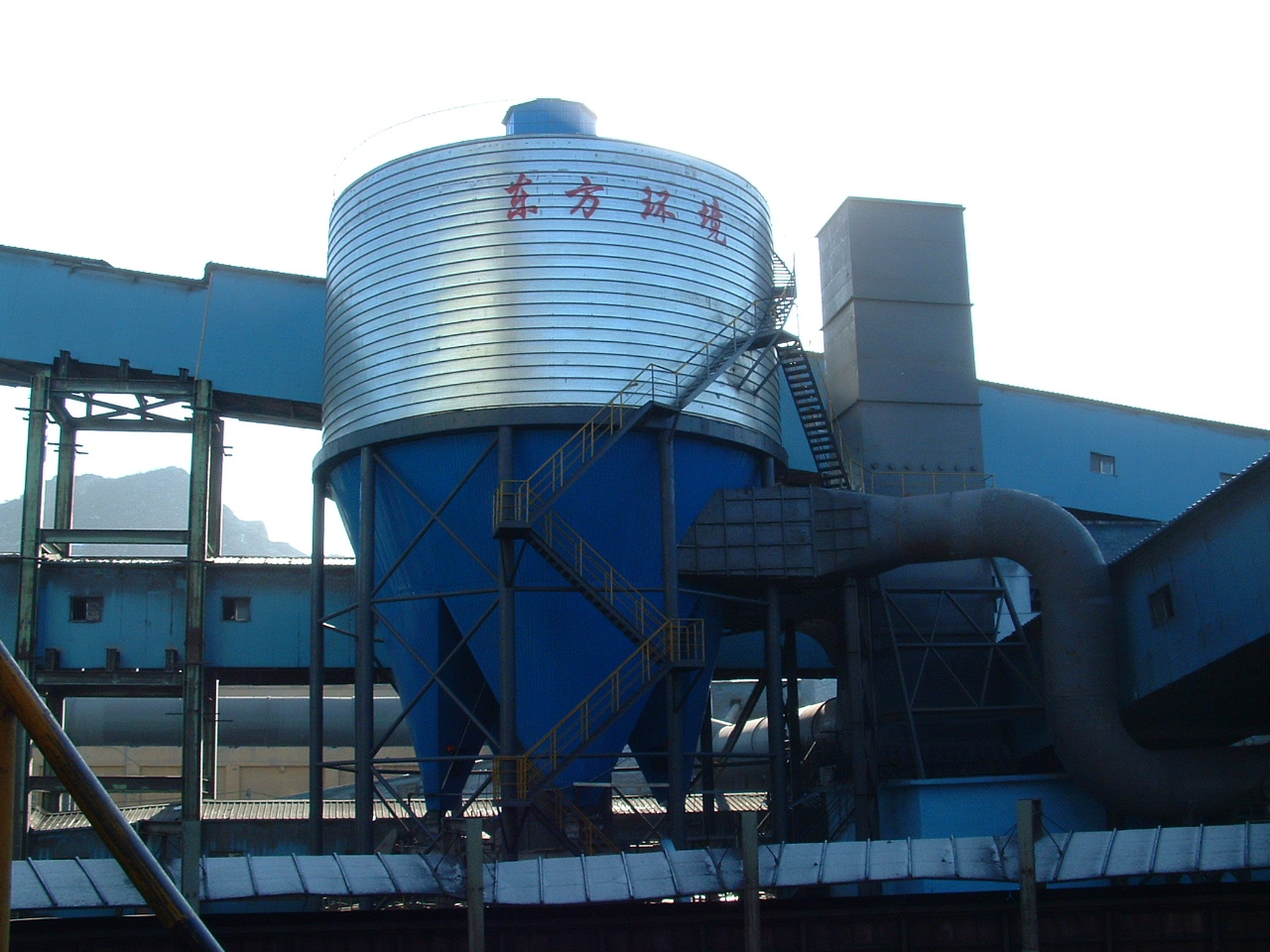

Aiming at the "high pollution" and "high energy consumption" industries, Dangfang has created many new technologies and new processes through continuous technological accumulation and technological innovation, and has successfully applied in more than 100 sets of furnaces at home and abroad.

Dongfang and Xi'an Jiaotong University have launched an all-round technology development cooperation of "production, learning and research". With technological innovation as drive, we will deeply explore cutting-edge technologies for energy saving and carbon reduction in the metallurgical industry, tap the potential of waste heat and waste energy recovery, and serve corporation Realize low-carbon, green and intelligent development and provide:Electric Furnace Flue Gas Waste Heat Recovery Technology、Sintering Flue Gas Circulation Emission Reduction Technology、Slag Dry Granulation and Waste Heat Recovery Technology.