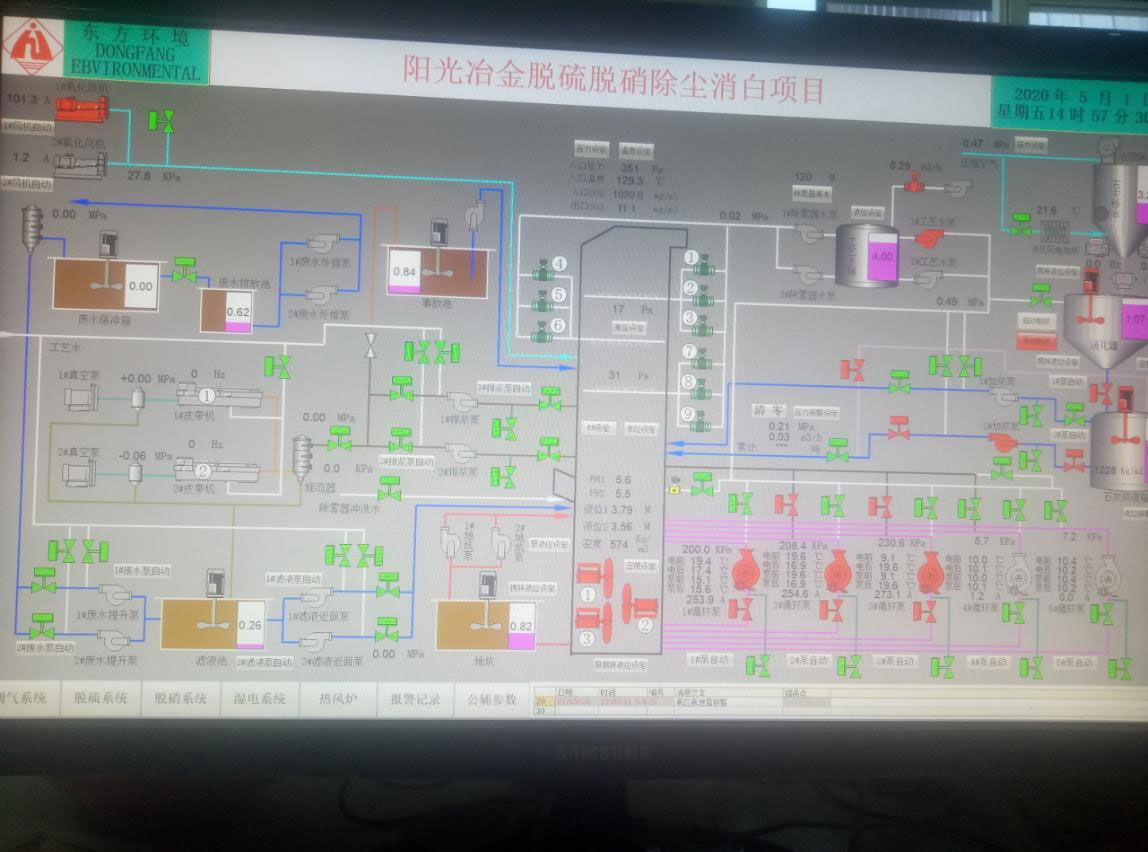

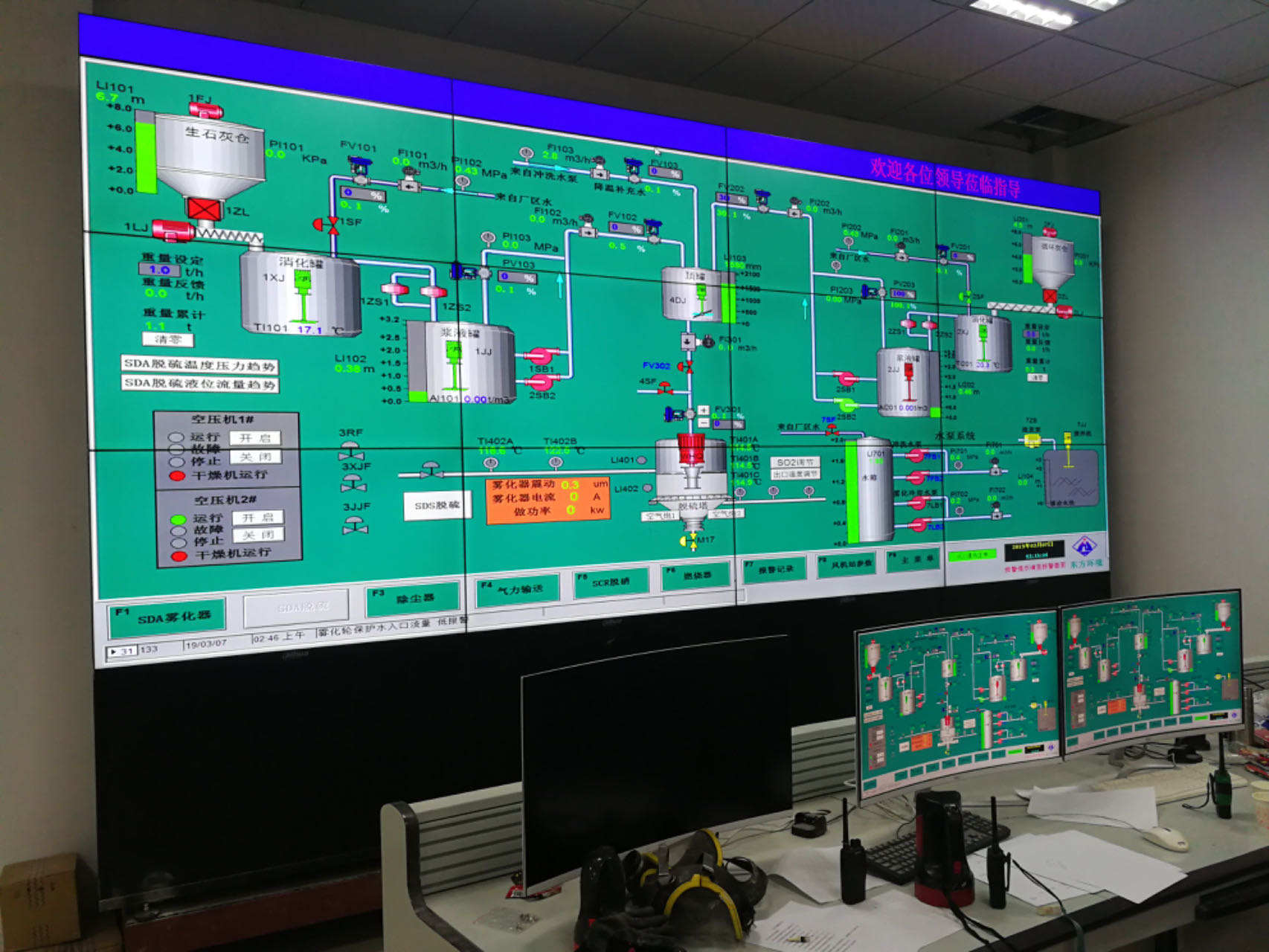

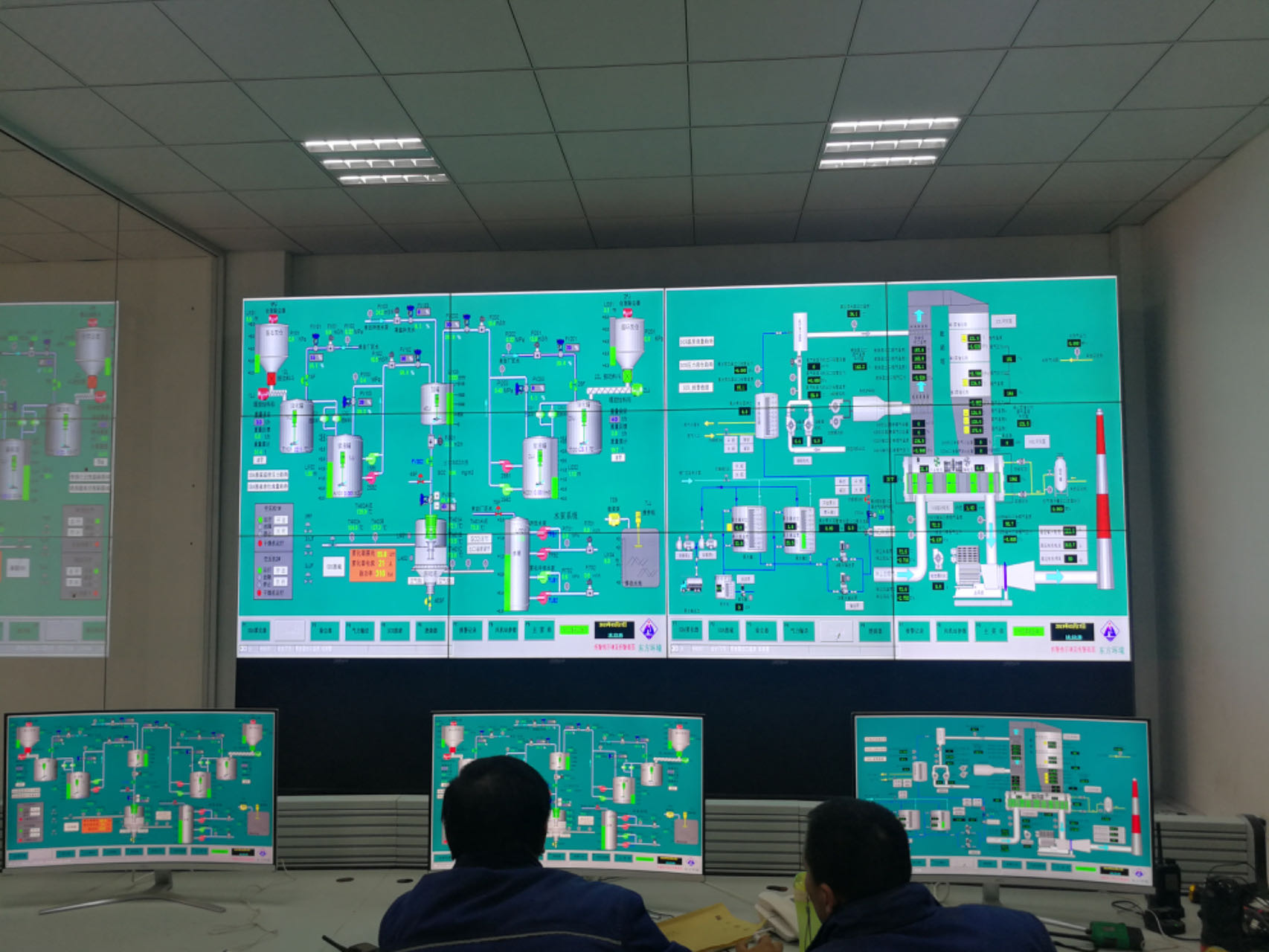

For the relevant environmental protection and energy-saving projects within company's business scope, we also provides a full range of professional operation and management services. Establish a plant-wide comprehensive management and control center for environmental protection and energy, a multi-functional intelligent control system, and an efficient and refined energy efficiency management and control platform. Through the comprehensive control and scheduling from point to surface, from module to the overall system, the efficient, stable and low-energy operation of the environmental protection and energy-saving equipment of the whole plant is realized.

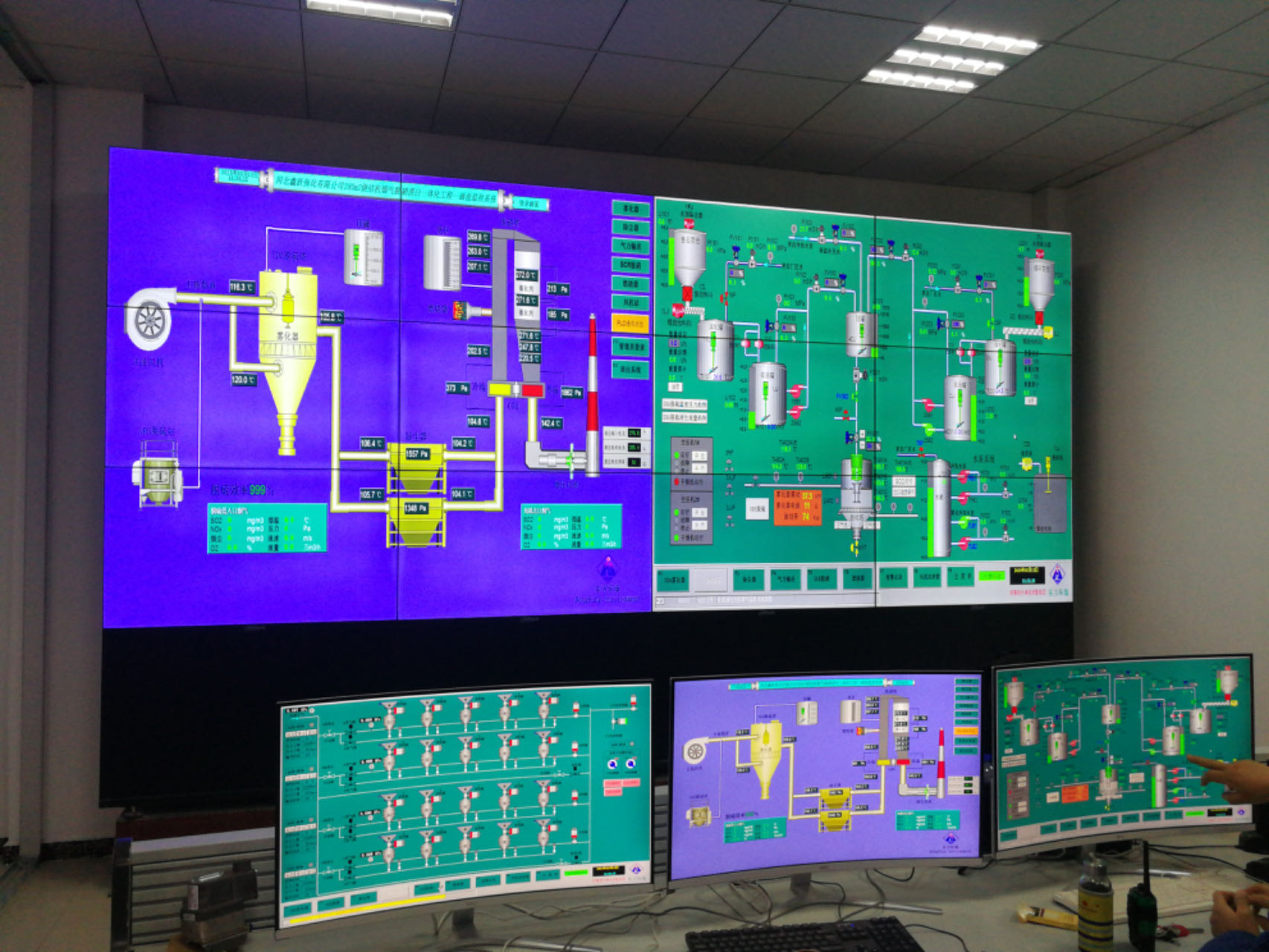

Jinan Yangguan Sintering Machine Wet Desulfurization + WESP + SCR Denitration + Whitening Project

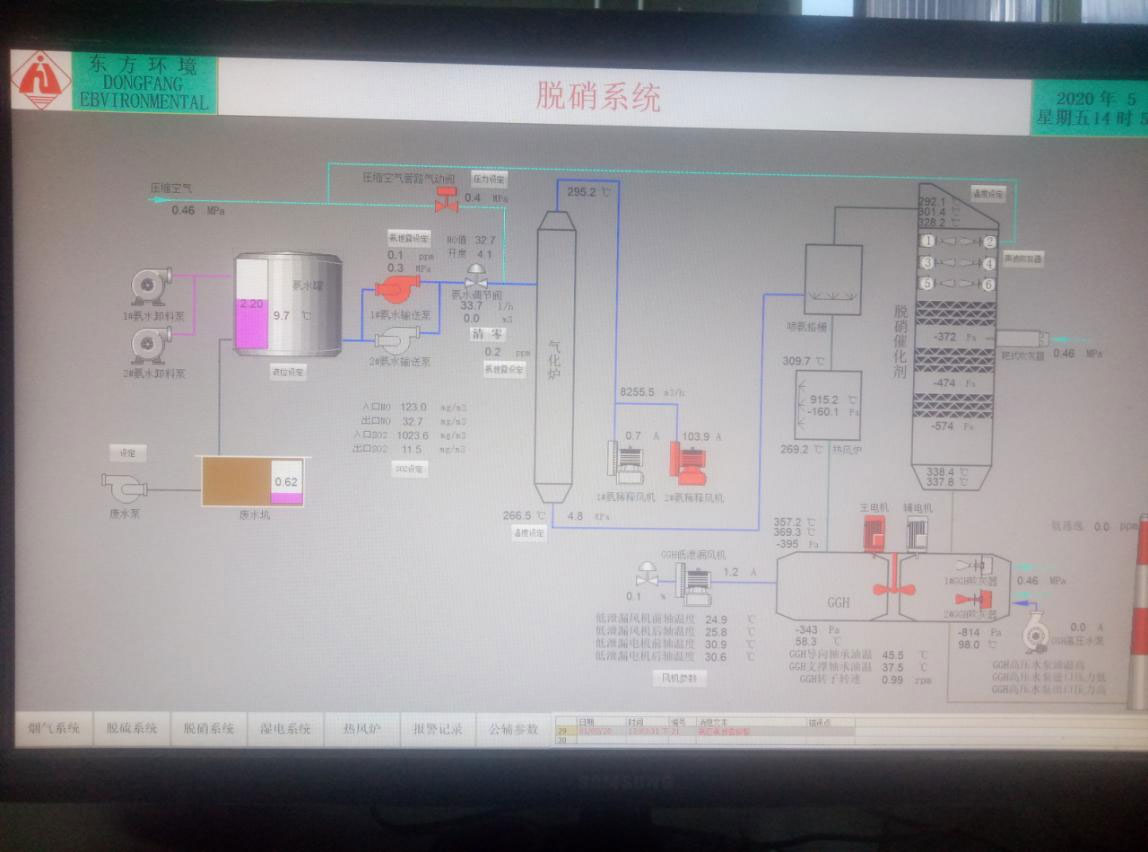

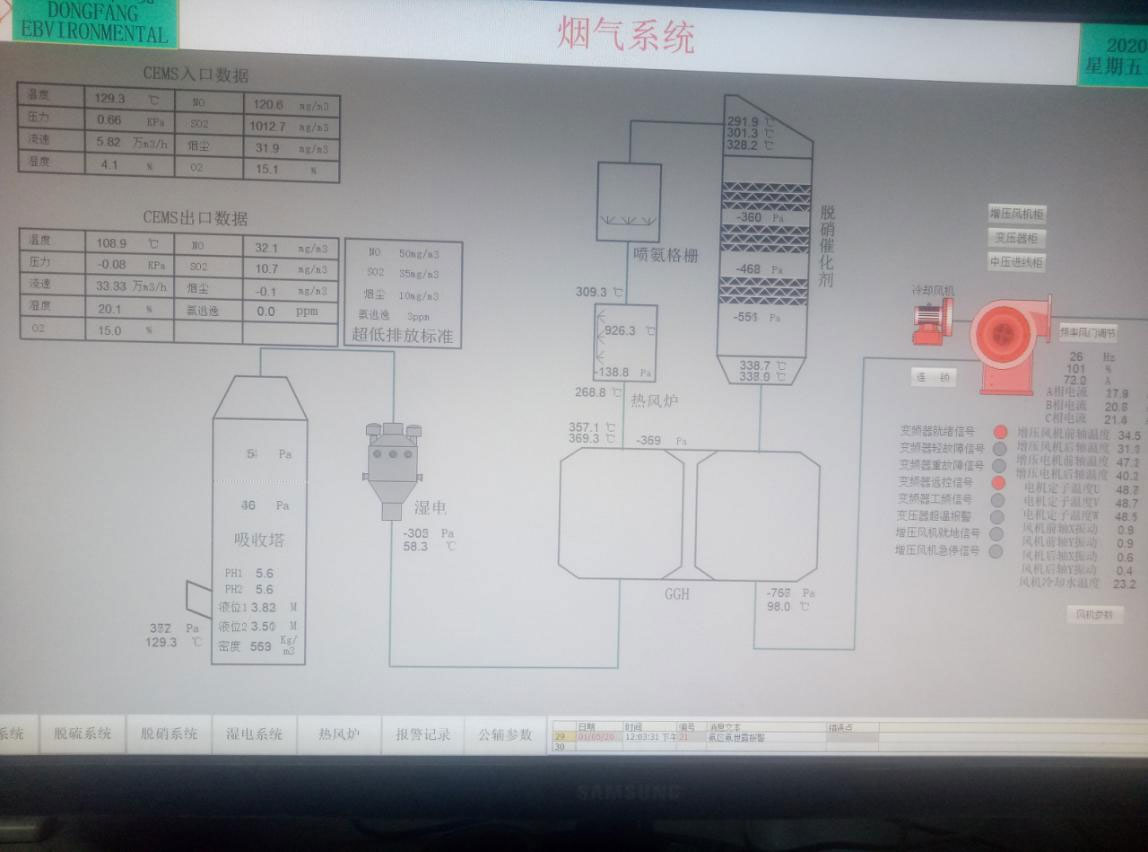

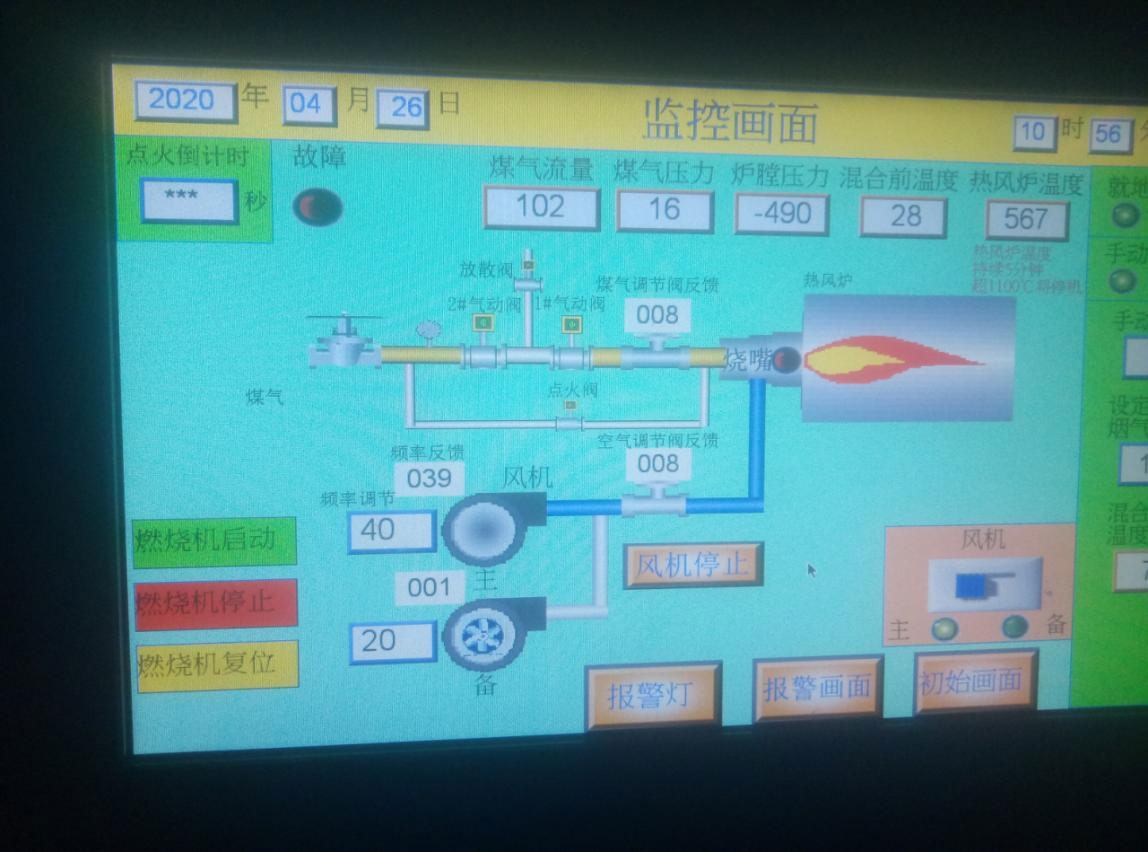

The integrated project of flue gas desulfurization, denitration, dust removal, and purification for the sintering machine of Laiwu Sunshine Metallurgical Co., Ltd. is a supporting environmental protection project for its relocation and construction of a new sintering machine. With the increasingly severe environmental protection situation, the requirements for the emission indicators of various pollutants are becoming increasingly strict. The sintering machine has been treated with flue gas desulfurization, denitration, dust removal, and purification to remove SO2 concentration from 3500mg to below 35 mg/Nm3, NOx ≤ 50mg/Nm3, and dust concentration reduced to below 5mg/Nm3.